Blog Details

16A vs 32A vs 63A Industrial Plugs and Sockets: A Complete Buyer’s Guide

Not sure whether to choose 16A, 32A, or 63A industrial plugs and sockets? This guide breaks down the differences, typical use cases, and key factors to help you decide.

In industrial environments, choosing the right electrical connection is essential—not just for compatibility, but for safety, performance, and long-term reliability. The difference between a 16A, 32A, and 63A plug or socket can affect your entire operation. Whether you're working on a construction site, a manufacturing plant, or an outdoor project, understanding which amperage suits your equipment is critical.

At Makewell Tech, we manufacture certified IP44 and IP67 plugs and sockets designed for harsh industrial applications. In this guide, we’ll help you understand how to choose the right option for your specific needs.

What Is Amperage and Why Does It Matter?

Amperage, measured in amps (A), refers to the amount of current an electrical component can carry. Higher amperage means the plug or socket can support more powerful equipment. However, using a higher amperage than required can be unnecessary and using too low an amperage can be dangerous. It’s important to match the amperage to your equipment's needs.

When to Use 16A Plugs and Sockets

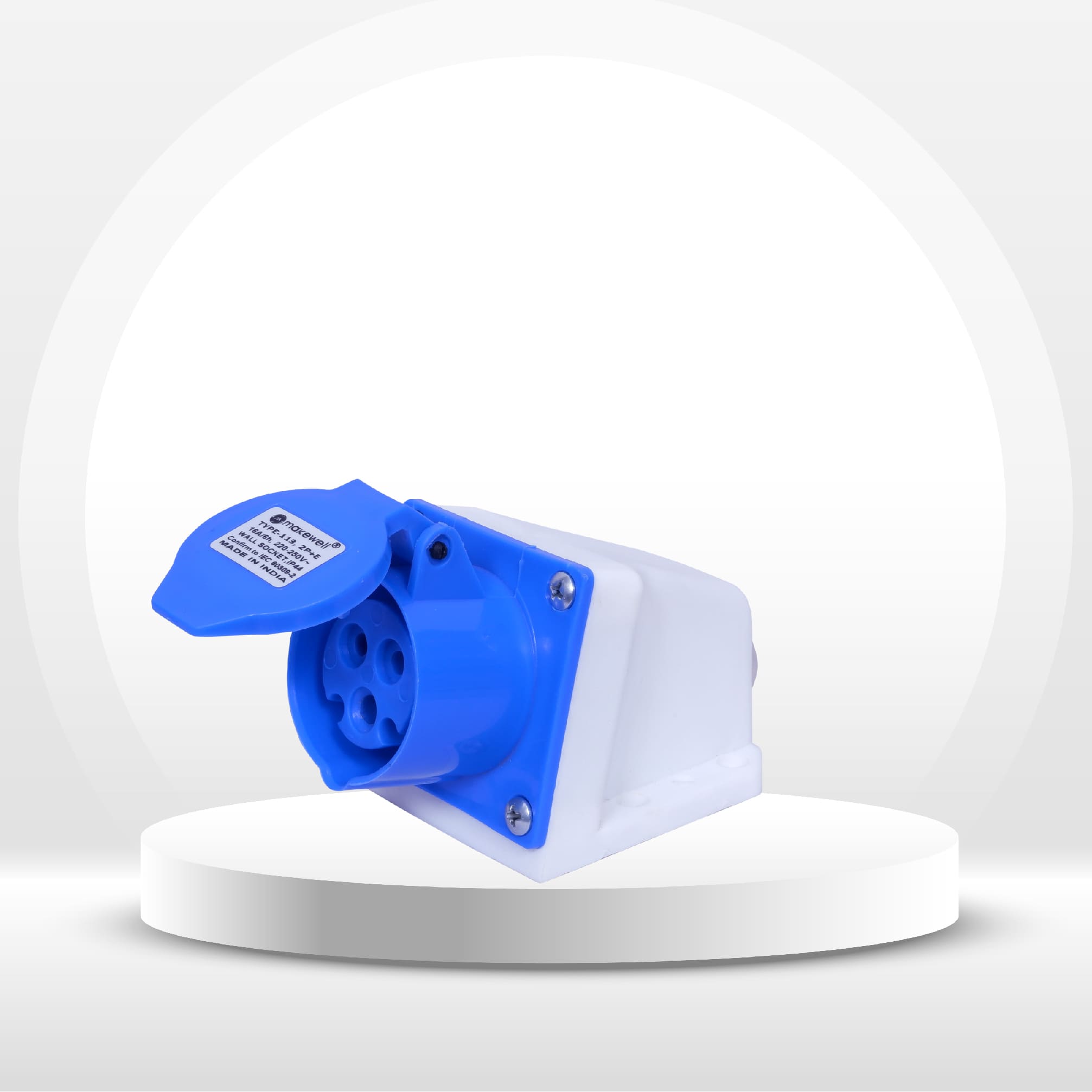

16A plugs and sockets are best suited for light-duty applications. They’re compact, easy to handle, and perfect for small electrical tools, portable lighting, and other low-power devices often found in workshops, event setups, or mobile workstations. If you need a plug for basic power tools or temporary lighting, 16A is ideal.

When to Use 32A Plugs and Sockets

32A plugs are designed for medium-load equipment. Common uses include machinery like small compressors, tower lights, and larger power tools. These are widely used on construction sites and in factories where the power demand is higher than 16A but not quite at the heavy-duty level. They strike a great balance between power capacity and portability.

When to Use 63A Plugs and Sockets

63A plugs and sockets are built for heavy-duty applications. This includes large industrial ovens, welders, HVAC systems, and production line equipment. These connectors are often used in permanent installations where high current is required consistently. They are robust, durable, and engineered for demanding industrial setups.

Safety and Compliance

Regardless of amperage, it's crucial that all electrical components meet safety standards. At Makewell Tech, every plug and socket is CE, ISO9001, RoHS, and CCC certified. Our products are also available in IP44 and IP67 ratings to withstand water, dust, and impact—especially important in outdoor or rugged environments.

Why Makewell Tech?

We offer a complete range of 16A, 32A, and 63A plugs and sockets

- Available in both IP44 and IP67 configurations

- Built using flame-retardant, shock-resistant materials

- Trusted by leading government and industrial sectors, including ISRO, BHEL, Indian Railways, and Defence

Categories

- Guide to 16A vs 32A vs 63A Electrical Components

- Electrical Products for Construction Sites

- Makewell’s Commitment to Quality Control

- Safety Practices When Working With Industrial Sockets

- How to Choose Between IP44 and IP67

- Wiring & Installation Tips for Industrial Sockets

- Industrial Plugs & Sockets in Oil & Gas

.png)