Blog Details

.png)

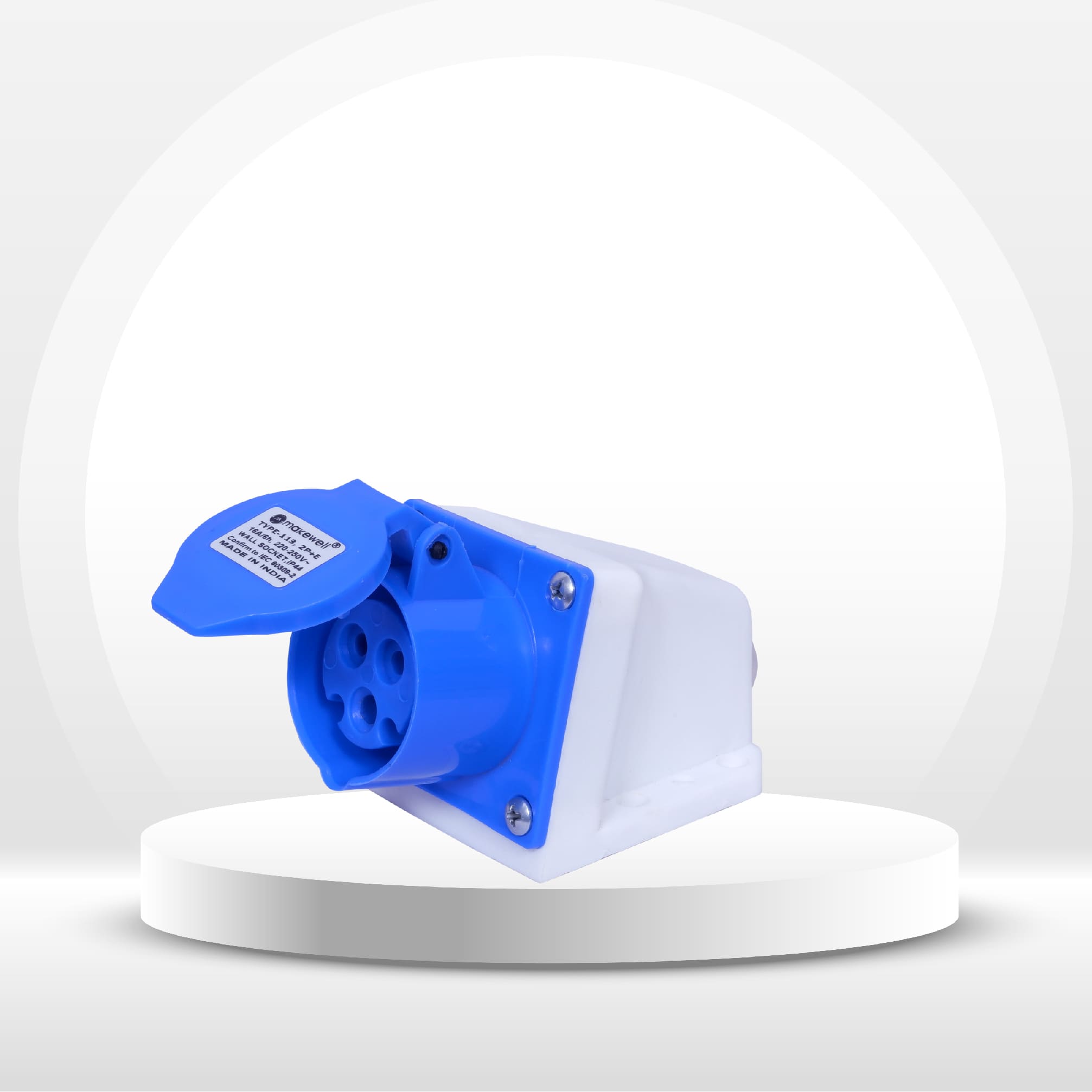

Why Industrial Plugs and Sockets Are Critical in Oil & Gas Environments

Oil & gas operations demand rugged, explosion-safe electrical connectors. Learn why IP67-rated industrial plugs and sockets are essential in this high-risk industry.

In the oil and gas industry, electrical safety is not just a priority—it’s a regulatory mandate. From onshore drilling fields to offshore platforms and refineries, electrical components are constantly exposed to water, dust, corrosive chemicals, and explosive gases. One of the most overlooked but critical components in such setups is the industrial plug and socket.

At Makewell Tech, we engineer IP67-certified plugs and sockets that meet the rigorous demands of the energy sector. In this post, we explain why the right connectors are vital for your oil & gas operations.

Why Safety is Non-Negotiable

The oil and gas environment presents unique electrical hazards:

- Presence of flammable gases and vapors (especially in Zone 1 & 2 areas)

- Exposure to corrosive agents like saltwater, fuel vapors, and chemicals

- High-pressure water jets and physical vibration from heavy machinery

Improper or uncertified connectors can cause:

- Arc flashes

- Short circuits

- Fire or explosion risks

- Costly operational downtime

Features Required in Oil & Gas Connectors

To function safely in such environments, industrial plugs and sockets must be:

1. Waterproof & Dustproof (IP67 Rated)

-Prevents moisture, mud, or oil from entering electrical connections

-Essential for outdoor and offshore usage

2. Flame-Retardant & Impact-Resistant

- Minimizes the risk of fire due to sparks or overload

- Survives harsh physical conditions

3. Certified & Compliant

- Must meet CE, RoHS, ISO 9001, and CCC standards

- Regulatory approvals ensure compatibility with international safety protocols

4. Easy to Install & Maintain

- Quick-connect and disconnect mechanisms

- Locking systems to prevent accidental removal

Where They're Used in Oil & Gas

- Powering drilling rigs and mobile site equipment

- Temporary power supply on oil platforms

- Lighting systems in hazardous zones

- Control panels in refineries and storage facilities

Our 16A, 32A, and 63A connectors are widely used for portable and fixed installations in these zones.

Why Makewell Tech?

- IP44 and IP67 sockets designed for harsh industrial use

- Fully certified under CE, RoHS, ISO 9001, CCC

- Trusted by ISRO, BHEL, Indian Railways, Defence, and energy contractors

- Flame-retardant, shock-resistant, and field-tested in real projects

- Customizable solutions for offshore and Zone 1/2 installations

Categories

- Guide to 16A vs 32A vs 63A Electrical Components

- Electrical Products for Construction Sites

- Makewell’s Commitment to Quality Control

- Safety Practices When Working With Industrial Sockets

- How to Choose Between IP44 and IP67

- Wiring & Installation Tips for Industrial Sockets

- Industrial Plugs & Sockets in Oil & Gas