Blog Details

How to Properly Wire and Install Industrial Plugs and Sockets

Installing industrial sockets? Learn the essentials—cable types, IP ratings, terminal tightening, and safety checks. Perfect quick guide for technicians and installers.

Installing an industrial plug or socket might seem straightforward—but getting it wrong can lead to short circuits, power loss, overheating, or even fires. In environments where heavy equipment, outdoor exposure, and high amperage loads are common, safe and proper wiring is absolutely critical.

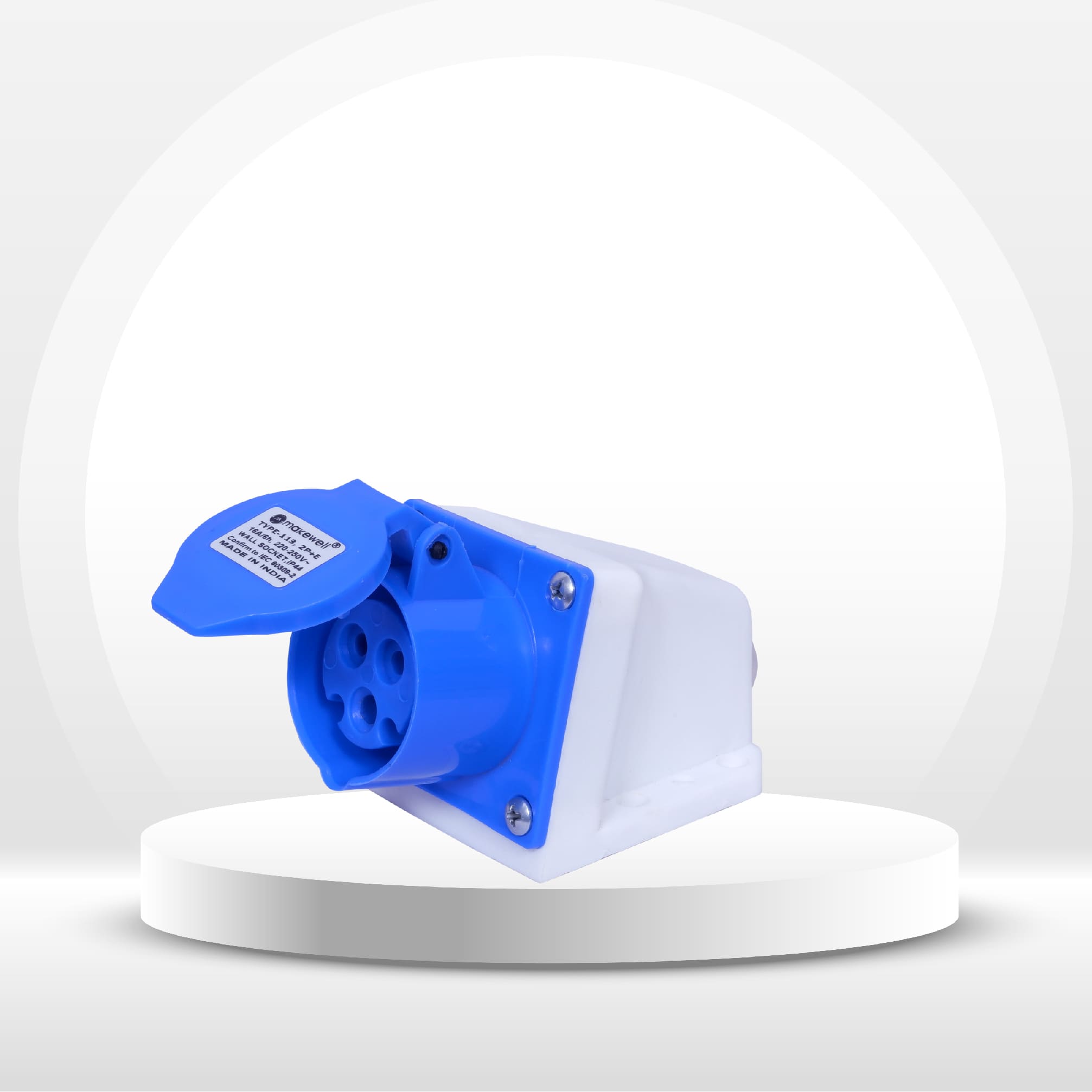

At Makewell Tech, our IP44 and IP67 industrial sockets are built for durability and performance—but even the best components must be installed correctly to ensure long-lasting operation. This guide will walk you through the key steps and best practices.

1. Choose the Right Socket for the Job

Before you begin installation, verify:

- Amperage rating: Use 16A for light tools, 32A for medium-duty, 63A for heavy machinery

- Voltage rating: Match the socket with the power supply and connected equipment

- IP rating: Use IP67 for outdoor/wet environments, IP44 for dry or semi-protected locations

Tip: Makewell sockets are clearly labeled with ratings and certifications (CE, RoHS, ISO9001, CCC).

2. Prepare Your Cables Properly

Use cables with the correct conductor size based on the load. Strip insulation cleanly and avoid damaging the copper strands. Always check:

- Cable insulation is rated for industrial use

- No exposed copper is left outside the terminal

- Use ferrules or lugs for better connection when necessary

3. Connect Terminals Securely

When wiring into the socket:

- Insert wires into the correct terminals (L1, L2, L3, N, and Earth)

- Tighten terminal screws to the manufacturer’s recommended torque

- Ensure a firm connection—loose terminals can cause heat buildup and fire

Reminder: Earth connection is mandatory for safety compliance.

4. Mount the Socket Safely

If the socket is panel-mounted or wall-mounted:

- Use proper mounting screws and ensure alignment

- Install a backbox or weatherproof enclosure for outdoor use

- Avoid placing sockets in areas prone to water pooling or physical damage

5. Perform Safety Checks

Before powering on:

- Check for short circuits using a multimeter

- Inspect insulation, terminals, and external casing

- Verify the tightness of cable glands and seals for waterproof models

- You should also test functionality under load and inspect heat build-up after 10–15 minutes of operation.

6. Follow Regulatory Compliance

All installations should comply with:

- IS/IEC standards for industrial electrical setups

- Local electrical codes and safety regulations

- Internal SOPs for maintenance, labeling, and periodic inspection

Why Makewell Tech?

- All products are CE, ISO, RoHS, CCC certified

- Rugged build quality with flame-retardant and shockproof housing

- Clear terminal labels and high-conductivity contacts

- Wide range of IP44/IP67-rated sockets in 16A, 32A, and 63A

- Trusted by major government & industrial clients

Categories

- Guide to 16A vs 32A vs 63A Electrical Components

- Electrical Products for Construction Sites

- Makewell’s Commitment to Quality Control

- Safety Practices When Working With Industrial Sockets

- How to Choose Between IP44 and IP67

- Wiring & Installation Tips for Industrial Sockets

- Industrial Plugs & Sockets in Oil & Gas

.png)