Blog Details

Top Safety Practices for Using Industrial Plugs and Sockets

Using industrial plugs and sockets? Follow these safety tips to prevent shocks, fire hazards, and downtime. A must-read for site engineers, electricians, and supervisors.

In industrial environments, electricity powers everything—from machines and lighting to control systems. But with high power comes high risk. One of the most overlooked yet critical components in any setup is the industrial plug and socket.

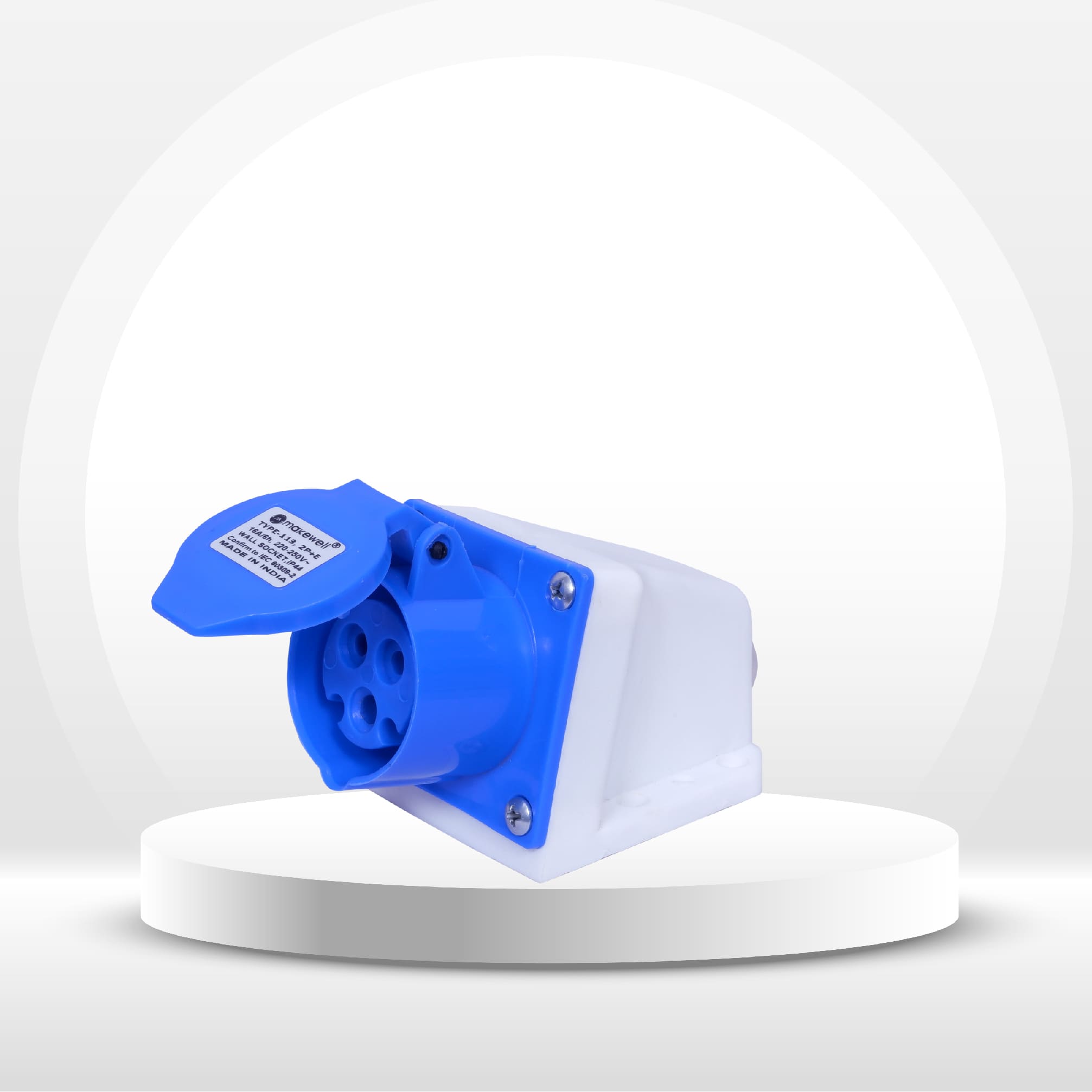

At Makewell Tech, we design our IP44 and IP67-rated plugs and sockets to meet the toughest safety standards. But safety also depends on how the product is used. In this post, we’ll share key safety practices that every professional should follow while working with industrial electrical connections.

1. Choose the Right Amperage & Voltage

Before installation, always confirm the equipment’s voltage and current rating. Never use a 16A plug where a 32A or 63A is required. Overloading can result in overheating, sparks, or damage to both the plug and connected equipment.

Tip: Makewell Tech offers certified 16A, 32A, and 63A sockets that are clearly marked for safe identification.

2. Understand IP Ratings for Environmental Protection

Industrial sockets are often used in dusty, wet, or outdoor environments. Choosing the wrong IP rating can expose users to water ingress, corrosion, or shock hazards.

- IP44: Suitable for dry and semi-protected areas

- IP67: Ideal for construction sites, outdoor setups, and wash-down zones

Always choose the right IP-rated product for your application.

3. Always Disconnect Safely

Never connect or disconnect plugs under live load unless the device is specifically designed for it. This can cause dangerous arcing and even explosions in certain environments.

Best Practice: Power off the supply, disconnect the load, then unplug.

4. Inspect Before Use

Check for visible signs of wear, corrosion, or cracks on the plug, socket, and cable. Damaged insulation or exposed wires can pose a major hazard.

At Makewell Tech, our products are made from flame-retardant, shock-resistant materials, but routine inspection is still necessary.

5. Schedule Regular Maintenance

Even with rugged components, regular checks are essential for:

- Tightness of terminals

- Moisture buildup

- Cable strain relief integrity

- Contact wear

Use a log system to track maintenance frequency and repairs.

6. Train Your Team

Improper usage often stems from lack of awareness. Provide your workers and technicians with safety briefings, equipment handling training, and updated SOPs (Standard Operating Procedures).

Remember: Safety isn’t just about equipment—it’s about people.

Why Makewell Tech?

- All products tested for thermal overload, ingress protection, and durability

- Certified under CE, RoHS, ISO 9001, and CCC

- Used by ISRO, Indian Railways, BHEL, Defence, and leading contractors

- Designed for long service life and safe performance

Categories

- Guide to 16A vs 32A vs 63A Electrical Components

- Electrical Products for Construction Sites

- Makewell’s Commitment to Quality Control

- Safety Practices When Working With Industrial Sockets

- How to Choose Between IP44 and IP67

- Wiring & Installation Tips for Industrial Sockets

- Industrial Plugs & Sockets in Oil & Gas

.png)