Blog Details

How Makewell Tech Ensures Uncompromised Quality in Every Plug and Socket

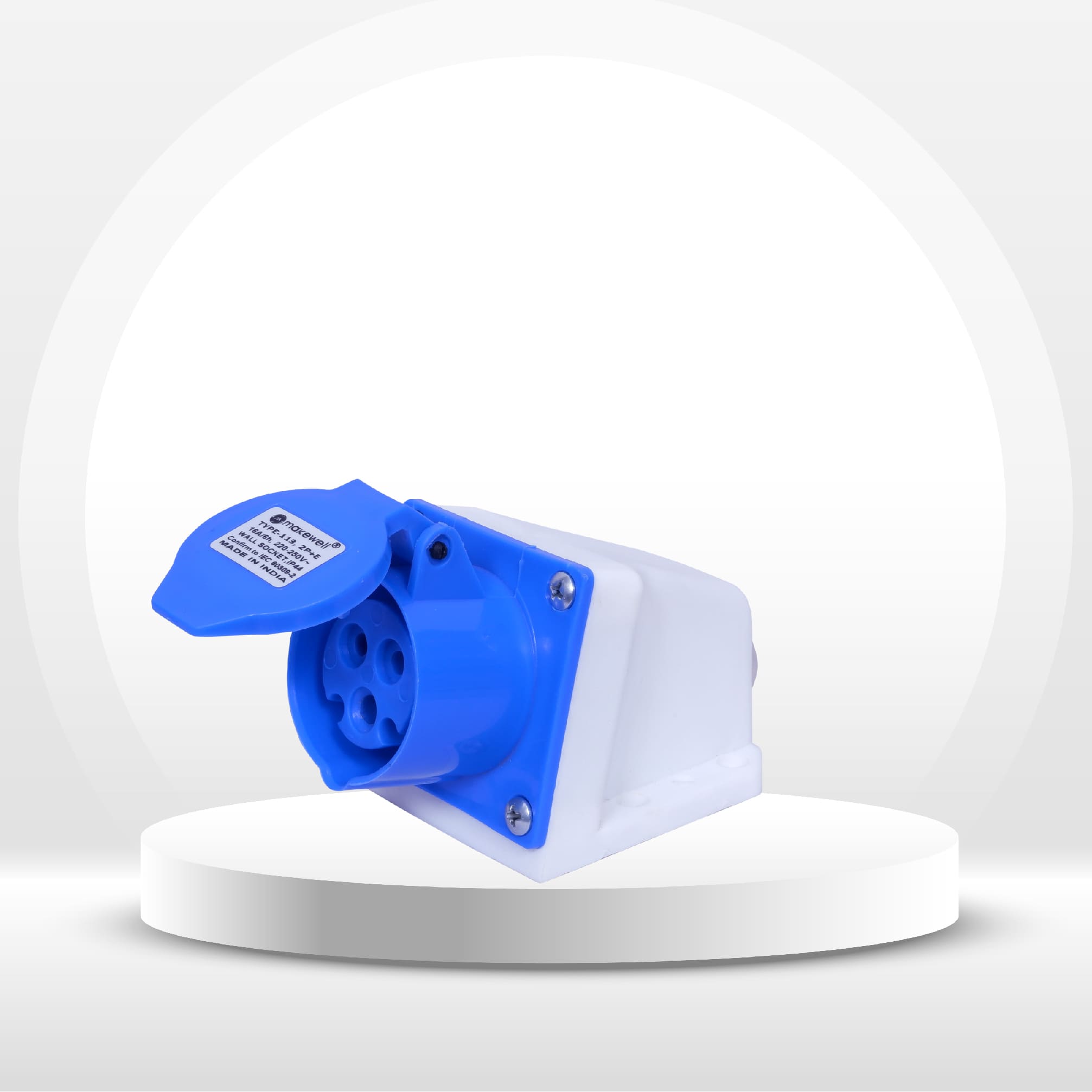

From certified materials to rigorous testing, learn how Makewell Tech guarantees long-lasting performance and safety in every industrial plug, socket, and connector we manufacture.

In industries where safety and reliability are non-negotiable, the quality of electrical components becomes a critical factor. At Makewell Tech, we don't just manufacture plugs and sockets—we build trust. With a strict quality control system at the heart of our operations, we ensure that every product that leaves our facility meets the highest global standards.

Our Quality Control Philosophy

Our quality assurance process begins long before the product hits the production line. From material sourcing to final packaging, every step is closely monitored, tested, and optimized to deliver maximum performance, safety, and durability.

Certified Manufacturing Process

Makewell Tech operates under a robust ISO 9001-certified quality management system, which ensures that every unit is produced with process consistency and defect prevention in mind. This means:

- Every batch undergoes visual and dimensional inspections

- All products are tested for electrical conductivity, mechanical strength, and sealing integrity

- We implement automated quality checkpoints at key production stages

Global Certifications

All Makewell Tech products carry the following certifications:

- CE (Conformité Européenne) – Compliance with European safety standards

- RoHS (Restriction of Hazardous Substances) – Non-toxic, environmentally safe materials

- CCC (China Compulsory Certification) – Recognized reliability in global markets

- ISO 9001 – Quality management system certification for manufacturing excellence

These certifications are not just badges—they reflect the trust our clients place in us, including renowned institutions like ISRO, Indian Railways, and BHEL.

In-House Product Testing

To maintain our standards, we conduct real-world simulations and stress tests, such as:

- Ingress protection testing (IP44/IP67) for water and dust resistance

- Heat resistance and thermal overload tests

- Shock and drop tests to ensure mechanical integrity

- Connector fit tests for seamless operation on-site

We also maintain batch traceability and documentation to ensure transparency and product history.

Continuous Improvement Culture

Our engineers and quality experts follow a Kaizen approach—focusing on continuous, incremental improvements. By regularly analyzing product returns, client feedback, and new industrial requirements, we upgrade our:

- Design durability

- Safety margins

- Packaging standards

- Testing technologies

Categories

- Guide to 16A vs 32A vs 63A Electrical Components

- Electrical Products for Construction Sites

- Makewell’s Commitment to Quality Control

- Safety Practices When Working With Industrial Sockets

- How to Choose Between IP44 and IP67

- Wiring & Installation Tips for Industrial Sockets

- Industrial Plugs & Sockets in Oil & Gas

.png)